A slower speed is recommended for acrylic. Especially at the start

and at the end of the process.

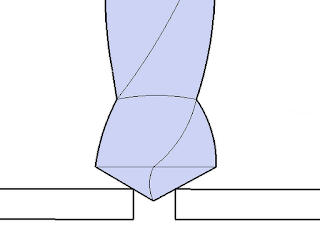

If you have a belt sander, you can also taper can also be modified from the original flat, 120 degree, to a sharper 60-90 degree point. This sharp angle allows the bit to easily enter and exit acrylic sheet without chipping. Meh. I didn't have easy access to a belt sander, and didn't bother, but still had no problem with my drilling.

I started by drilling a 1/8" pilot hole, and moved up to a final 5/16". This particular size of hole will allow the 2.5mm mini-plug shown below, to enter with jsut a bit of snugging up. The fit seems probable to be even a bit waterproof. Water resistant at least. I ordered this patch cable from eBay, the shortest, lightest, 4-pin mini-plug to RCA cable I could find, listed as: "2.5mm TRS plug to RCA female adaptor" (sic) $2.88 from from eBay seller flyjoy2009.

If you have a belt sander, you can also taper can also be modified from the original flat, 120 degree, to a sharper 60-90 degree point. This sharp angle allows the bit to easily enter and exit acrylic sheet without chipping. Meh. I didn't have easy access to a belt sander, and didn't bother, but still had no problem with my drilling.

I started by drilling a 1/8" pilot hole, and moved up to a final 5/16". This particular size of hole will allow the 2.5mm mini-plug shown below, to enter with jsut a bit of snugging up. The fit seems probable to be even a bit waterproof. Water resistant at least. I ordered this patch cable from eBay, the shortest, lightest, 4-pin mini-plug to RCA cable I could find, listed as: "2.5mm TRS plug to RCA female adaptor" (sic) $2.88 from from eBay seller flyjoy2009.

Finally, once you've drilled your hole(s), use a counter

sink to relieve the sharp 90° corner on the outside edge. (I just used a large high-speed steel bit, and twirled it with my fingers in the hole a few times to lightly counter sink the surface, where stress cracks might occur.

Lastly, since I fly with an external monitor only on occasion, but fly along a lakefront on a semi-regular basis, this is how I can add some nominal waterproofing my no-longer water proof camera housing on those days when I'm not cabling my camera, but flying over water and might need it to protect the camera in the event of a water crash.

I picked up a 3/16"" rubber washer at HomeDepot for a few cents, and a 1/8" Chicago Screw from a leather supply wholesaler.

A Chicago screw, (also known as a sex bolt, or barrel nut) is a post-shaped nut that is internally threaded, and comes witth an accompanying machine screw. The post section has a very low-profile, flat base, which will just barely fit inside the housing with the GoPro enclosed. You'll still have room for the anti-Fog inserts, or a couple of strips of "Sham-Wow" style cloth, a home-brew substitute, condensation inhibitor. The base of the post will be either a solid, or open back.

You might beg one of these little gizmos from a local shoe repair person, or pick up a dozen 1/8"pairs from Tandy, or off the internet for a few bucks.

I bought a package of ten (pairs/sets) of "SCREW POST - 1/8" nickle OPEN-BACK" Chicago screws from Tandy Leather for $3.99. Tandy has brick and mortar stores all over North America, and also sell on-line.

When installed, the camera just barely fits inside the housing. It pushes the camera slightly off center, however, and the on/off button won't work properly. So what you need to do is clamp the base in a pair of Vice-Grips, and file the curve off the bottom of the post base, further flattening it, as shown below.

You might get the same effect rubbing the bottom of the post section against some Emery paper, but filing is fast - and only takes a minute or two - just enough to reduce the thickness of the base by about that of a piece of paper or two, so that the camera goes in and out without rubbing, and all the buttons work.

I gave it an overnight bucket test, and the rubber washer will keep the casing both reasonably waterproof, and air-tight enough to keep the humidity out too.

I wouldn't want to risk scuba diving with this system at any depth, but it will hopefully keep the camera dry in the event I ever have to put my motor down in Lake Ontario, or Lake Simcoe, in which case I'll probably have more to worry about than my camera, anyway.

Lastly, since I fly with an external monitor only on occasion, but fly along a lakefront on a semi-regular basis, this is how I can add some nominal waterproofing my no-longer water proof camera housing on those days when I'm not cabling my camera, but flying over water and might need it to protect the camera in the event of a water crash.

I picked up a 3/16"" rubber washer at HomeDepot for a few cents, and a 1/8" Chicago Screw from a leather supply wholesaler.

|

| CHICAGO SCREW |

You might beg one of these little gizmos from a local shoe repair person, or pick up a dozen 1/8"pairs from Tandy, or off the internet for a few bucks.

I bought a package of ten (pairs/sets) of "SCREW POST - 1/8" nickle OPEN-BACK" Chicago screws from Tandy Leather for $3.99. Tandy has brick and mortar stores all over North America, and also sell on-line.

When installed, the camera just barely fits inside the housing. It pushes the camera slightly off center, however, and the on/off button won't work properly. So what you need to do is clamp the base in a pair of Vice-Grips, and file the curve off the bottom of the post base, further flattening it, as shown below.

You might get the same effect rubbing the bottom of the post section against some Emery paper, but filing is fast - and only takes a minute or two - just enough to reduce the thickness of the base by about that of a piece of paper or two, so that the camera goes in and out without rubbing, and all the buttons work.

I gave it an overnight bucket test, and the rubber washer will keep the casing both reasonably waterproof, and air-tight enough to keep the humidity out too.

I wouldn't want to risk scuba diving with this system at any depth, but it will hopefully keep the camera dry in the event I ever have to put my motor down in Lake Ontario, or Lake Simcoe, in which case I'll probably have more to worry about than my camera, anyway.

This

system of Chicago screws and rubber washers also makes for a workable

solution for attaching homemade MOLLE straps to the back of a GoPro,

which you can see in my nest post on attaching MOLLE straps to a GoPro.

POST SCRIPT: My local Home Depot sells 1/4" Chicago screws in packs of 4 pairs, for $2.99. They are aluminum, open backed, with threads all the way to the bottom of the base posts. These will work, if you carefully cut them down to 1/8". I tried cutting some closed-base posts, and they didn't work. Turns out, the threads did not go all the way down, and at the 1/8" point, they were just smooth cylinders.

e

e

No comments:

Post a Comment